Product Spotlight – Spray Foam Sealants

Table of Contents

As standards of energy efficiency and for designing higher quality buildings increase, “canned” insulating spray foam sealants have grown in popularity over the past 25 years among professional contractors and DIYers.

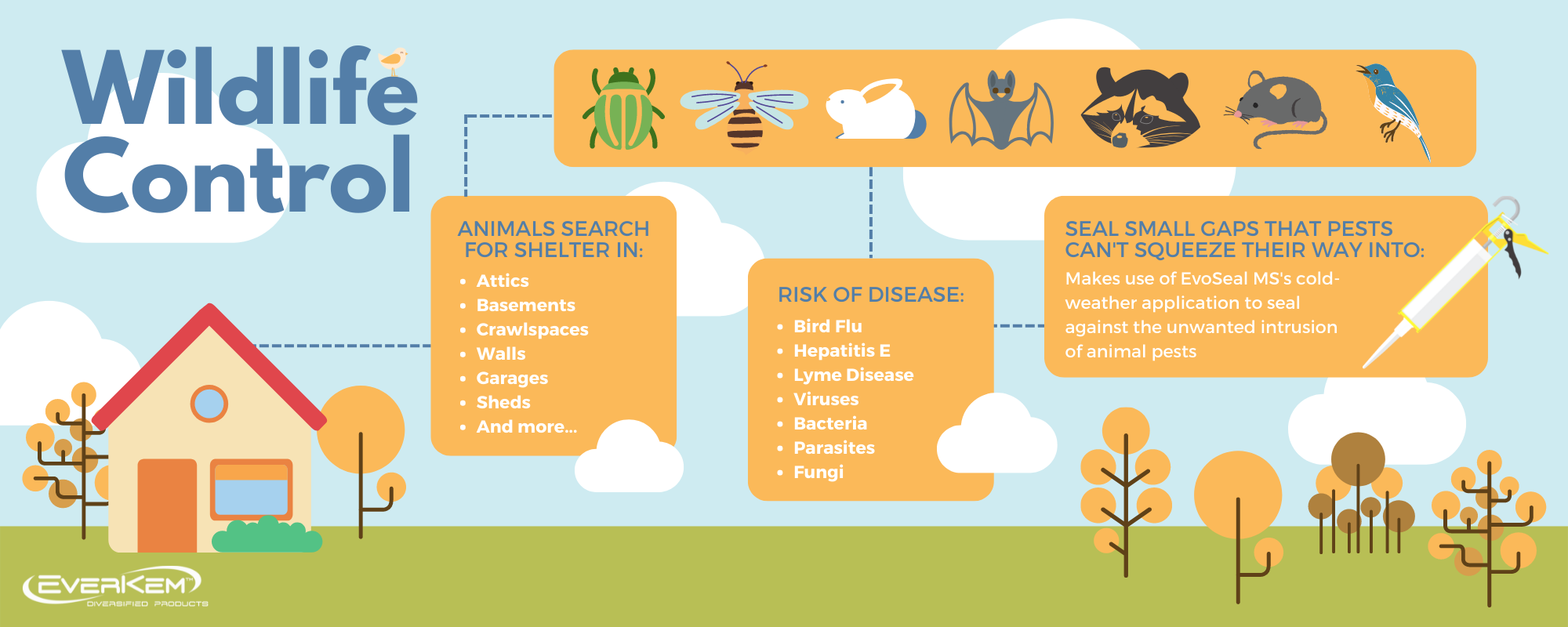

Often used by professional insulation contractors, window installers, plumbers, electricians, HVAC, and DIY/homeowners, insulating foam sealants are one of the most economical and versatile sealants available. This is due to foam sealants’ high expansion properties, yield coverage, and effectiveness as a barrier to dust, sound, air, moisture, bugs, and rodents.

Polyurethane foam was initially developed in the 1940s for military and aviation applications. It was not until the late 1970s that new technology allowed spray foam insulation to be used widely in home construction and improvement projects.

Polyurethane spray foam chemistry primarily consists of 2 main ingredients, isocyanate and polyol resin. When mixed, sprayed, and fully cured, the foam expands roughly 30 to 60 times its liquid volume.

As the technology for equipment, manufacturing, and packaging for polyurethane foam chemistry improved, one-component canned spray foam became more portable and efficient. The ability to dispense the foam material using an aerosol-blowing agent with a straw or gun dispensing tool allowed installers to apply the foam in small “bead-type” applications.

As a result, one-component canned insulating spray foam (OCF – one-component foam) has been a game changer for professional contractors, manufacturers, industrial installers, and DIYers in pursuit of higher quality buildings and meeting the rigorous energy conservation requirements we have today.

OCF sealants fill joints, seams, gaps, and cracks in wall cavities wherever air leakage can occur. Due to their expansion properties and dispensing methods, OCF sealants are highly effective for use in hard-to-reach areas and offer usage for far more applications than just insulation purposes.

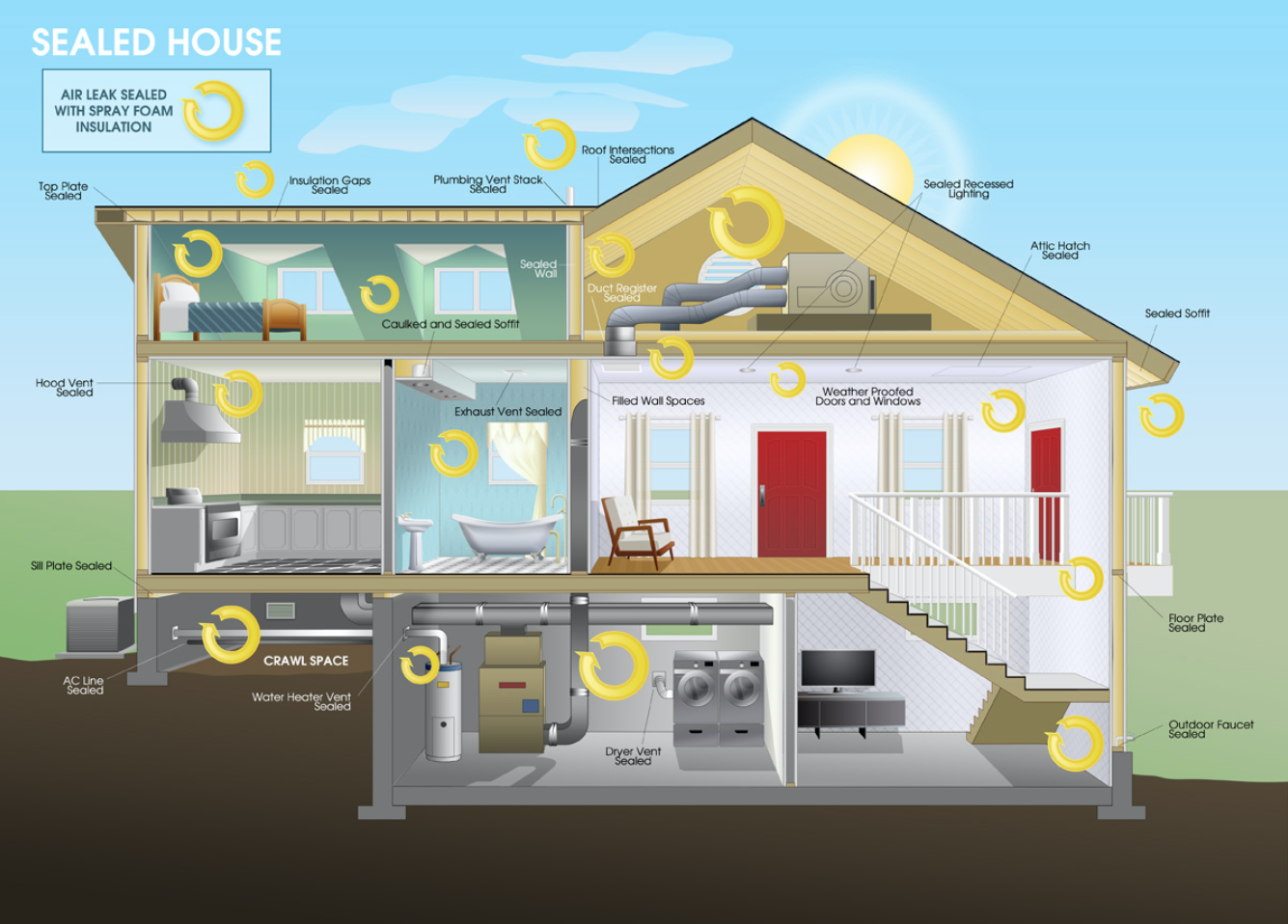

INSTALLERS TYPICALLY USE EXPANDING FOAM FOR INTERIOR APPLICATIONS TO PREVENT AIR INTRUSION BY FILLING GAPS IN AND AROUND:

- basements

- crawl spaces

- attics

- floors and ceilings

- sill plates

- windows and doors.

Examples include sealing around the exterior of baseboards and vents, electrical boxes and plumbing pipes, electrical cables, or HVAC duct penetrations.

Click image to enlarge

Source Credit: Why Spray Foam, “Advantages of Spray Foam”

Due to the varying formulations available on the market and the usefulness of OCF chemistries, some spray foam sealants are also used for exterior applications and as a sealant or adhesive for landscape projects, including stone wall repair, pond/waterfall fillers, and to secure landscape blocks. Foam sealants are also widely used in the recreational vehicle and transportation industry.

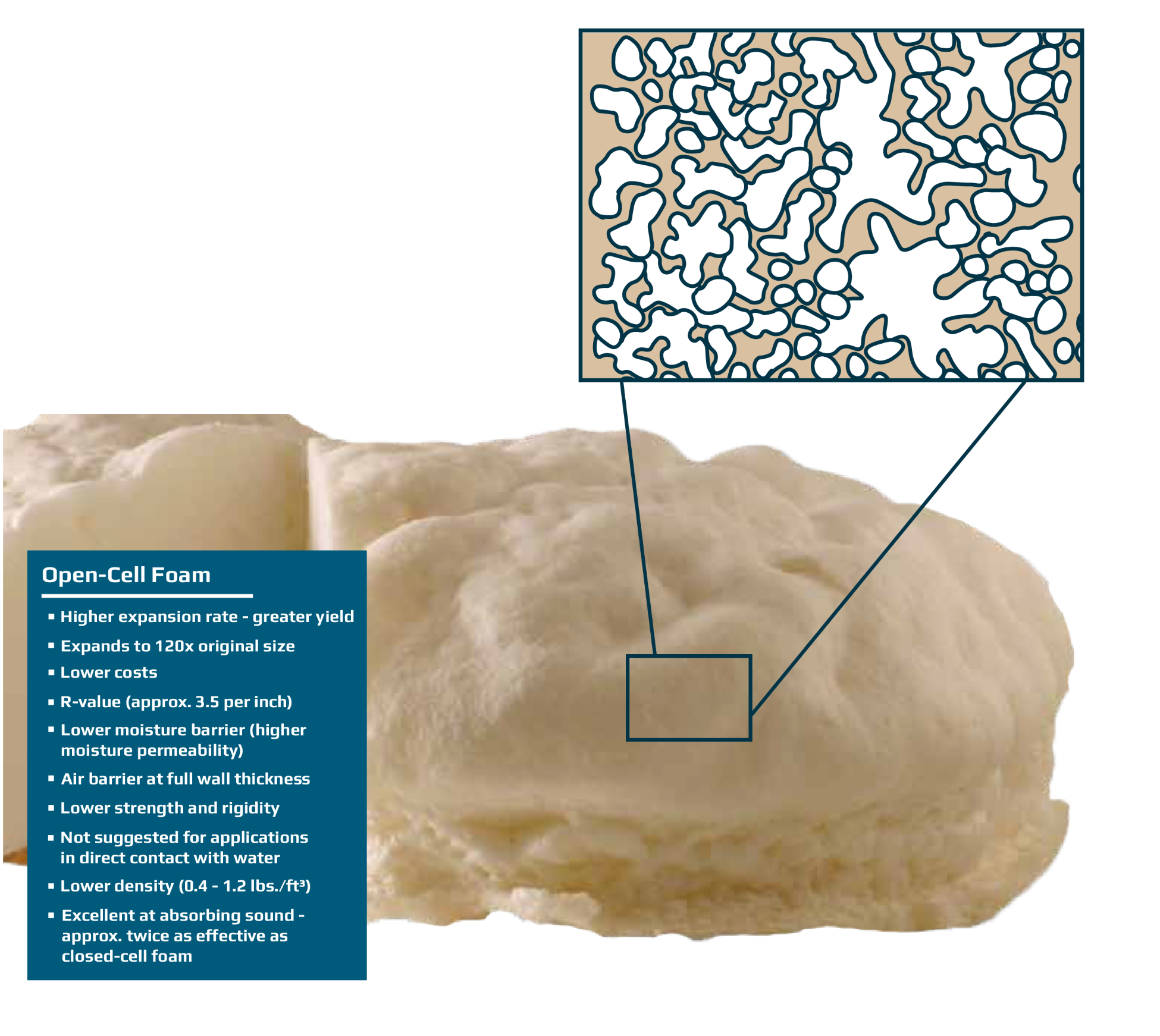

Spray foam insulation is referred to as open-cell or closed-cell because of the difference between the makeup of the cell structure – those tiny air bubbles – within the cured foam. Open-cell foam is full of cells that are not completely encapsulated, making the foam softer and more flexible with a lower core density. As a result, open-cell foam has a greater expansion rate than closed-cell foam, which leads to greater yield and lower costs. However, due to its structure, a greater thickness is often needed to perform as an effective air barrier compared to closed-cell foam. The lighter-density open-cell foam will perform well in dampening sound, but is not the optimal choice as a barrier to water and moisture.

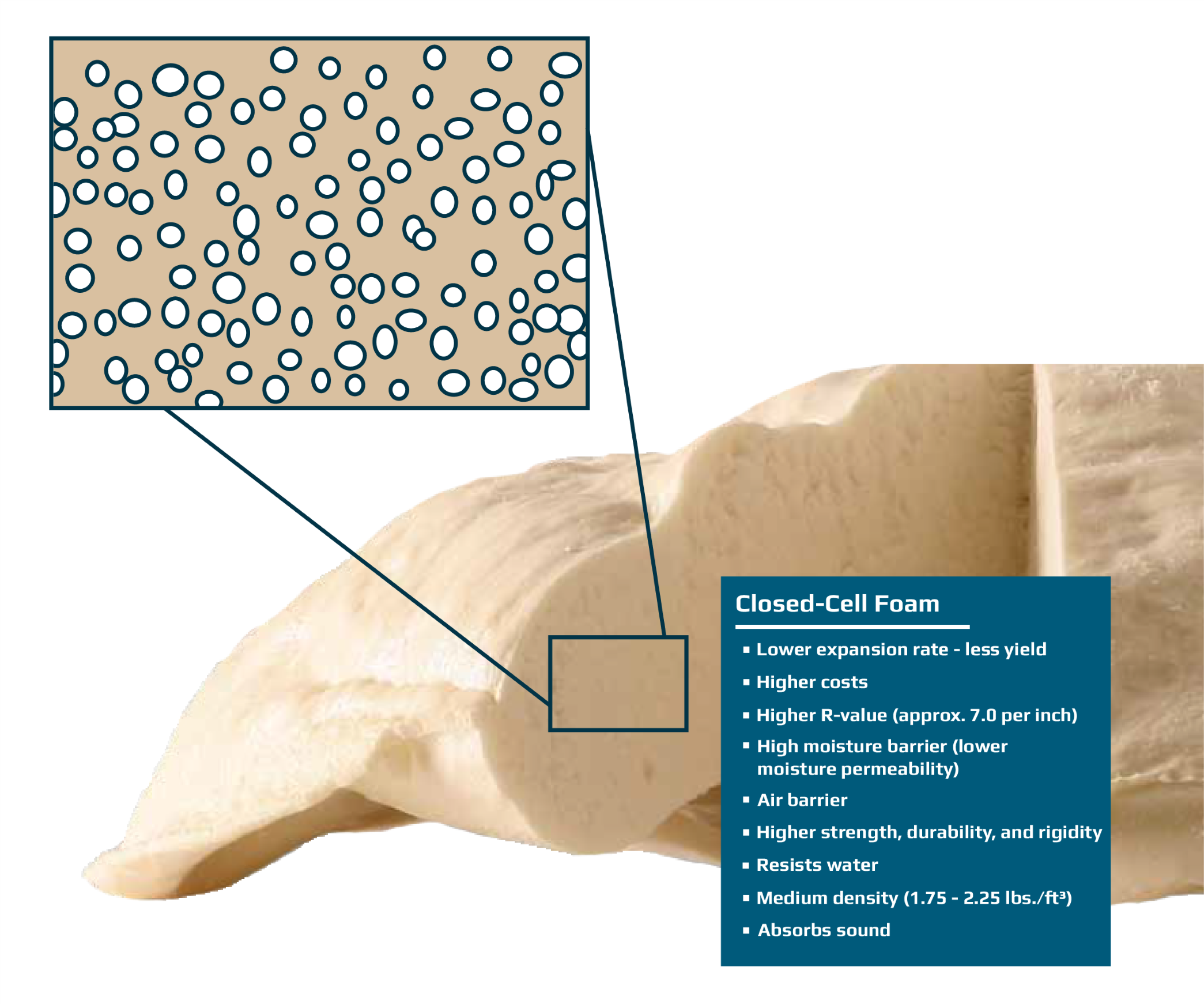

On the other hand, closed-cell foam consists of densely packed cells fully encapsulated within the foam material; it has a higher density and is more rigid and stable than open-cell foam. Because the cells are entirely closed and pressed together, it has a higher R-value and performs better as an air and moisture barrier. Due to the heavier density of the closed-cell foam, the material absorbs sound, though not as effectively as the lighter-density open-cell foam. This results in a lower yield which comes at a higher price.

The American Architectural Manufacturers Association (AAMA) has a published standard AAMA 812-19, which addresses “The Voluntary Practice for Assessment of Frame Deflection When Using One Component Polyurethane Foams for Air-Sealing Rough Openings of Fenestration Installations.” This practice identifies pressure build and dimensional stability as the key attributes contributing to the deflection of fenestration products from using one-component polyurethane foams and provides test protocols for assessing these key attributes.

Using spray foam sealants around the perimeter of windows or doors can be a critical component to installation for sealing drafts and increased energy efficiency. However, using an unsuitable OCF sealant for this application that has not been tested to AAMA 812 could potentially warp, distort, or bow out the window frames, causing costly damage. It is essential to ensure the insulating foam product manufacturers’ labeling and installation instructions specifically reference window and door applications. This should include claims of low-pressure build or minimal expansion and offer 3rd party testing documentation for AAMA 812.

In non-fire-rated Type V residential construction, openings around vents, pipes, ducts, cables, and wires at ceiling and floor level are to be filled or “fireblocked” with an approved material to resist the free passage of flame and products of combustion. Although traditional fireblocking materials such as lumber, wood, particleboard, gypsum, cement-based millboard, or batts/blankets of mineral wool or fiberglass insulation, and noncombustible ASTM- E136 rated caulking compounds are considered, the International Residential Code (IRC) Section R302.11 Item 4 allows for the interpretation of using fireblocking foam sealants in some building department jurisdictions.

Over the past 15+ years, manufacturers of foam sealants have introduced orange or pink-colored foam sealants marketed toward fireblocking applications, to fill the open voids around wires, pipes, ducts, and other mechanical penetrating items in single-family new home construction.

Initially, noncombustible ASTM-E136-tested caulking materials were the only acceptable material for this application; however, OCF manufacturers have gained approval in some building municipality jurisdictions by running a modified ASTM-E814 test to be recognized by the ICC International Code Council) Evaluation Services as an alternative Fireblocking material.

Although the foam products are “marketed” for fireblocking applications, they are flammable, not fireproof, and used more as an air sealant to minimize the drafts that carry flame throughout the building. It is best to check with your local municipality for the Fireblocking requirements in your area to ensure the acceptability of the foam as an approved Fireblocking material by the authority having jurisdiction (AHJ).

Although many OCF sealant manufacturers label their foam products for interior and exterior uses, most OCF sealants are not UV stable. The yellow, tan, or orange-colored cured foams are most often susceptible to discoloration and degradation when exposed to ultraviolet light.

Multipurpose Black Insulating Foam Sealant is an excellent solution for discreetly filling unwanted gaps across various applications where product appearance could be a factor. Examples include landscaping, pond design, waterfall design, small openings in home exteriors as a pest or rodent deterrent, as well as vehicle undercarriages and marine applications.

Polyurethane foam sealants are moisture-cure, where freshly dispensed foam absorbs moisture from the humidity in the air to adhere, expand, and cure properly. Having adequate temperatures, ventilation, and suitable humidity is ideal for achieving excellent adhesion, expansion, and product performance. Although the vast majority of polyurethane-based sealants are installed at warmer temperatures, around 65°F- 80 °F (18°C-27°C), geographical location and seasonality can have a negative effect on the installation process and curing characteristics of OCF sealants.

Polyurethane foam sealants are moisture-cure, where freshly dispensed foam absorbs moisture from the humidity in the air to adhere, expand, and cure properly. Having adequate temperatures, ventilation, and suitable humidity is ideal for achieving excellent adhesion, expansion, and product performance. Although the vast majority of polyurethane-based sealants are installed at warmer temperatures, around 65°F- 80 °F (18°C-27°C), geographical location and seasonality can have a negative effect on the installation process and curing characteristics of OCF sealants.

As a result, some OFC manufacturers offer extreme temperature or high humidity formulations to ensure the product and installer always experience optimal performance year-round. But suppose you don’t have access to extreme-temperature foam sealants. In that case, it is considered best practice to keep your foam sealant canisters and dispensing tools stored at room temperature, warm them up before use, and slightly wet or mist the substrate with water during application.

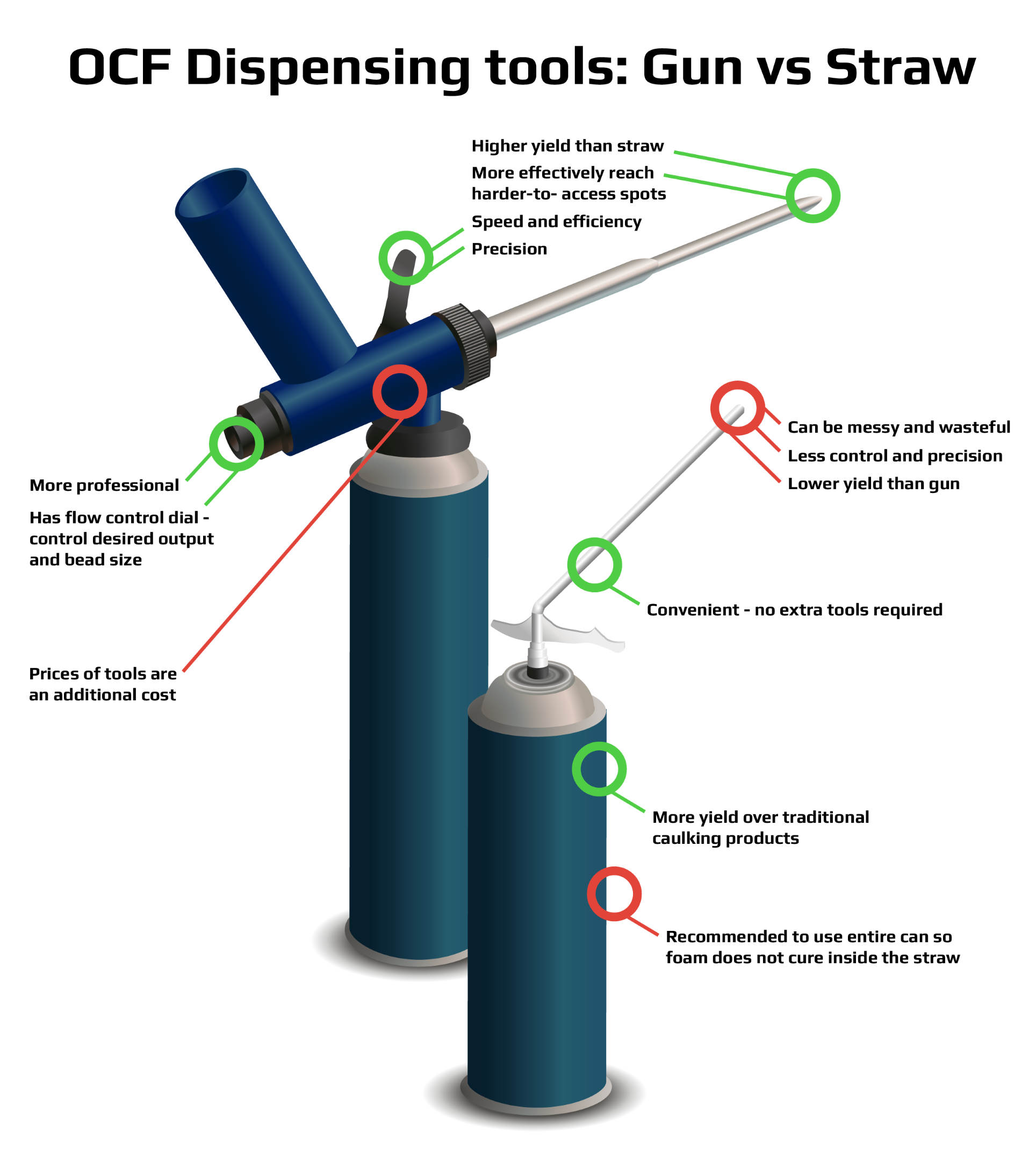

One-component foam sealants are packaged in aerosol cans and use a straw or specially designed foam gun to dispense the uncured liquid foam. While the traditional straw-dispensed method is convenient and allows the user to apply the foam with no other tools or equipment, the gun-dispensing method is typically used by professional installers that use foam sealants on a regular basis.

The most popular packaging type of OCF sealant is a straw-dispensed aerosol can. After rigorously shaking the can, the installer screws on a clear plastic dispensing straw, inverts the can with the valve end down, and then presses on the plastic straw to dispense the material. This packaging option is commonplace on retail shelves and found in contractor and industrial supply houses, lumber yards, hardware stores, and big box stores.

The most popular packaging type of OCF sealant is a straw-dispensed aerosol can. After rigorously shaking the can, the installer screws on a clear plastic dispensing straw, inverts the can with the valve end down, and then presses on the plastic straw to dispense the material. This packaging option is commonplace on retail shelves and found in contractor and industrial supply houses, lumber yards, hardware stores, and big box stores.

Although this dispensing option is convenient and offers improved yield over traditional caulking products, straw-dispensed foam can be messy and wasteful due to the lack of control and precision. Additionally, if the user does not dispense the whole can and the foam cures in the straw, there will have difficulty dispensing the rest of the unused can.

To prevent this “single-use” scenario, we recommend using the entire can upon opening and purchasing additional unused straws if available. Another option is unscrewing the straw to spray foam gun cleaner, acetone, or WD-40 through the used straw to clean out the curing foam so that the straw is clean and can be reused later. Straw-dispensed foam canisters are typically packaged in 12, 16, 20, or 24 fl oz options.

More popular amongst professional contractors and high-volume users, foam gun dispensing tools are the preferred choice for those that require speed, precision, and efficiency in installation. After shaking the can, the applicator inverts the “gun foam” OCF canister and screws it onto a foam gun dispensing tool.

This tool has a flow-control dial that allows users to adjust the bead size to match their desired output and control the dispensed foam more comfortably. The longer foam gun barrel enables the installer to apply the foam in harder-to-access spots more efficiently and effectively.

Foam guns can range from close to “disposable” in quality at a very economical price to higher priced, professional models made of high-quality components designed for precision, durability, and longevity. Foam gun dispensing tools come in a variety of options with different handles, valves, flow-control dials, and barrel lengths. Of course, you get what you pay for, and the installer should properly clean and maintain their foam guns like any other tool they depend on to perform top-quality craftsmanship.

Necessary when using a foam gun dispensing tool, foam gun cleaner is part of maintaining and caring for your foam gun. Cured foam tends to build up on the tip and clog the nozzle, and lack of care and cleaning could result in shorter gun life. Foam gun cleaner is basically “acetone in a can” and is sold in 12 and 16-fluid-ounce canisters that screw onto the foam gun. Once the can is attached to the gun, the user squirts the foam gun cleaner through the dispensing tool until the foam is completely removed from the barrel and nozzle. Then the foam gun is ready to be stored.

The foam cleaner typically comes with a screw-on spray nozzle that allows the user to spray the exterior of the gun or on a rag to wipe any excess foam that may have accumulated during usage. If the user needs to continue using the foam gun, it is recommended to switch foam canisters without cleaning the inside of the gun and leave the foam canister on the gun until removed for storage.

We have compiled some resources to help you use your OCF foam effectively and efficiently. This includes tips and tricks, safety, and frequently asked questions.

BEST PRACTICES:

- Always follow the manufacturer’s instructions on the label of the product

- Follow all safety instructions and wear the proper PPE – Protect eyes and avoid getting uncured foam on your skin or in your hair

- Always store cans upright and in a cool, dry area (do not lay cans on their side)

- Before foaming, be sure to warm the can to room temperature

- Ensure area is clean and nearby substrates are properly taped, covered, or protected to avoid mess and costly cleanup or damage

- For optimal yield, shake the can very well (at least 30 to 60 seconds)

- For straw-dispensed foam, be sure to invert can with valve end down

- For gun-dispensed foam, do not over-tighten the foam canister on the gun

- Practice laying down beads before foaming to become familiar with using the straw or gun dispenser and the foam expansion process

- Do not overfill the void, only fill cavities to 1/3 full (approximate 1/2” bead) to allow for adequate expansion

- Mist area to be foamed with water. Foam sealants are moisture cured, and the water will assure cross-section curing and optimal expansion and yield

- For using the gun dispensing system, always leave the can on the gun. The pressure from the aerosol can prevents moisture from entering the gun

- Be sure to lock the flow adjustment valve at the back of the gun dispensing tool to prevent accidental discharge

- If you remove the empty foam canister and plan to store the gun, be sure to use gun cleaner to clean the inside of the foam gun, wipe off the tip, and remove any uncured foam

- If uncured foam contaminates any unwanted surfaces, immediately use foam gun cleaner, mineral spirits, or acetone to remove foam before curing. Once foam is cured, it is very difficult to remove and often has to be removed mechanically

- Direct sunlight will slowly degrade most foam products unless specifically formulated for exterior uses. Oil or water based paint can be used to coat the foam and protect it from UV degradation

For more ways to master using your spray foam, check out Family Handyman’s article, “17 Ways to Master Using Spray Foam at Home” and The Spruce’s article, “10 Smart Uses for Expanding Foam.”

One component spray foam is dispensed as a liquid. It expands and cures into solid foam insulation and sealant.

One component foam is used to fill and seal small cracks and gaps (i.e., around door frames, window frames, and electrical devices) where air leakage and energy loss occur. Foam sealant comes in variations for sealing windows and doors, fire blocking, and construction adhesive.

- Residential construction

- Home weatherization

- Commercial construction

- Air barrier and gap filling

- Insect, Rodent, and Pest deterrent

- Cold storage

- Roofing maintenance and repair

- Storage tanks

- Pipe insulation

- Insulated transportation repair and maintenance

- Specialty vehicles

- HVAC systems

Open-Cell Foam

Open-Cell foam cures soft and flexible and is an excellent air and sound insulator. Open-cell foam has a low density, with each cell in the foam being broken or not completely encapsulated, allowing air to fill all of the spaces in the material. Open-cell foam has a greater expansion rate than closed-cell foam, which could lead to greater yield and lower cost; however, a greater thickness may need to be applied to perform as an effective air barrier. Open-cell foam does not perform well as a barrier to moisture and water.

Properties of Open-Cell Foam:

- Higher expansion rate – greater yield – more economical

- R-Value approximately 3.5 per inch

- Higher moisture permeability (lower moisture barrier)

- Less effectiveness as an air barrier (Greater thickness needs to be applied)

- More flexible, softer, and less strength and rigidity

- Lower density (0.4 – 1.2 lbs/ ft3)

- Great acoustical and sound-dampening properties

Closed-Cell Foam

Closed-Cell foam consists of densely packed cells fully encapsulated within the foam material, making it harder and more rigid than open-cell foam. Closed-cell foam has a higher R-Value and performs better as an air and moisture barrier. It is not as effective as a sound barrier, and the lower yield comes at a higher price.

Properties of Closed-Cell Foam:

- Lower expansion rate – less yield – less economical

- R-Value approximately 7.0 per inch

- Lower moisture permeability (higher moisture barrier)

- Greater effectiveness as an air barrier (Lower thickness to be applied)

- Firm, harder, and more strength and stability

- Higher density (1.75 – 2.25 lbs./ft3)

- Less effective for acoustical and sound dampening

Although most OCF Sealants are considered closed-cell foam, they are typically a percentage of open or closed-cell content. Depending on the manufacturer and the intended application, different formulations may consist of predominately closed-cell content or open-cell content. Understanding the physical properties and performance capabilities can help the user decide which product is most suitable for the intended application.

R-value measures the capacity of an insulating material to resist heat flow. Also referred to as “thermal resistance,” the R-value of different insulating materials is based on ASTM test method and is determined by material type, thickness, and installed weight per square foot, and not by thickness alone.

- Store OCF Sealants in dry area between 60° – 90° F (16° – 32°C.)

- Once the can is on the gun, always leave the can on the gun to ensure no moisture from entering the system to clog up the gun

- Always store can upright

- Storage above 120° F (49°C) can cause leakage due to pressure

- Do not store near sources of heat or ignition

- Storage below 60° F (16° C) can cause crystallization of liquid components and affect the quality

- Always check the product label for more information

- Keep out of reach of children

- Storage above 90°F (32°C) will reduce product quality and life. Do not store at temperatures above 120°F (49°C). Do not freeze

- Straw Foam – Leave straw adaptor attached. Use within 2 weeks

- Gun Foam – Leave can of foam attached to foam gun and use within 30 days

Use foam gun cleaner or acetone and a clean cloth or paper towel. Always test a small area to ensure the foam gun cleaner or acetone will not damage the surface. Do not use solvents on skin.

Wear chemical-resistant gloves and protective clothing to avoid skin contact. If foam does come in contact with skin, wipe off as much of the liquid as possible and wash well with soap and water. Do not use solvent to try to remove the foam. Residual foam on the skin will gradually wear off. If a rash or persistent irritation develops, consult a physician.