Reflecting on 2022, we have seen Covid shutdowns, material and labor shortages, natural disasters, and even war. With all of this craziness, I have been fortunate enough to say that we have made some industry friends all around the world. We have banded together to help one another when the supply chains got tight.

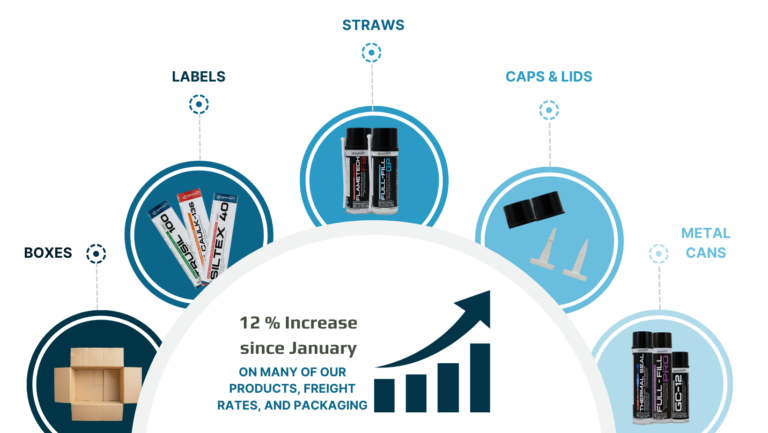

Now, as we venture into the unknown of 2023, whispers of a possible recession and slowdown can still be heard over the cries of “where is my order!” And after almost three years of battling the trend of stockouts and climbing prices, we are starting to see some materials plateau and even come down. We have seen numerous acquisitions this year, which makes me grateful to still be standing as an independent US manufacturer. But with the good, there is always the bad; we are still getting increases on other raw materials and packages, as most of you are experiencing too.

If you are currently working with us or follow our Caulk Talk Industry Advisories, you will already know that acetoxy and other silicone-based material costs have decreased considerably. In contrast, acrylics, butyls, polyurethane-based sealants, foam sealants, hybrid sealants, and most other product chemistries have remained tight on supply.

High demand for alternative materials was one of the themes of 2022, and MS polymer hybrid sealant chemistry products were often substituted for the lack of polyurethane and silicone-based sealants. As a result of this added demand, the costs remain high with limited supply and extended lead times on key raw materials. Demand continues to be very strong and unyielding for acrylic latex chemistry products, which include our construction adhesives and smoke and fire protection products.

Butyl chemicals for our butyl rubber sealants and fire-rated putty pads, and anti-ox electrical grease compounds remain under pressure, with elevated costs holding steady. We have received no good estimates from suppliers as to if or when supply will stabilize and costs may subside. Finally, polyurethane foam sealants supply and costs have been steady since force majeure on several of the primary raw materials has been lifted. We hope to find relief for polyurethane sealant raw materials as we progress into 2023.

I believe we will see more stability in the chemical, sealant, and adhesive industry, and demand and opportunities will continue to be strong into the summer months. In the meantime, the Everkem Team will head into 2023 knowing that the past three years have only made us stronger. We have new determination and commitment to be your voice and your choice for all of your caulk, sealant, and construction chemical compound needs.