While signs of some materials like silicone sealants seem to be loosening up, others like acrylic and polyurethane chemistries are still in severe shortage, and costs continue to rise. The Ukraine War is the newest complicating factor in an ever-changing landscape, resulting in escalating freight prices alongside the tightening of the supply of oil-based chemicals and solvents. Additionally, it has further affected the cost and availability of many of our sealant and adhesive products and other manufactured goods that we depend on daily.

Shortages for acrylics and most auxiliary chemicals for acrylic-based formulations have severely affected the supply and availability of key products such as Firestop-814+, SilTex 40 kitchen & bath Caulk, and our Acura Seal acrylic urethane sealant.

Materials for polyurethane foam sealants remain in short supply, and their costs continue to rise. We have also experienced cost increases for most of our packaging items: Boxes, plastics (tubes, cups, pails, and bottles), and labels.

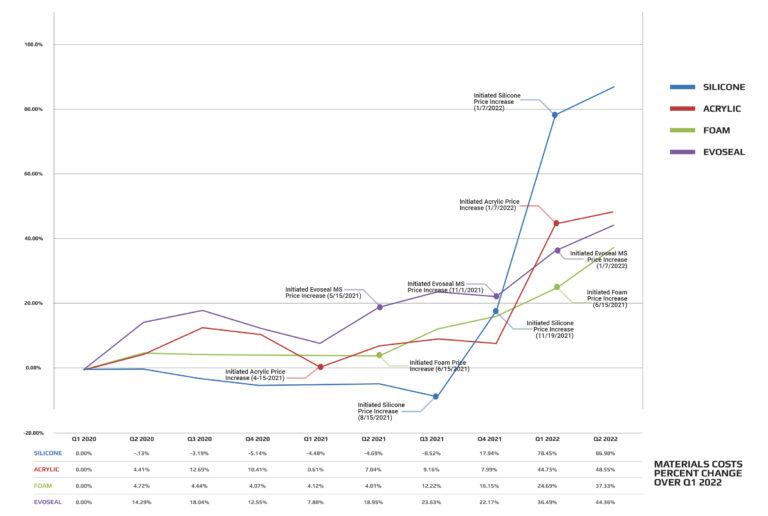

In charting out the numbers, we’re still seeing an upward trend in our costs of manufactured goods, increasing at similar rates to those in Q2 and Q3 of 2021. Looking back at those quarters, I couldn’t imagine things could worsen, but they have continued to climb steadily to points we once thought unimaginable.

The chart above illustrates the percent change in materials costs across several key chemistries

from a Q1 2020 start date. These costs include:

- Raw materials

- Container items such as cartridges and squeeze tubes

- Components such as cartridge plungers and lids

- Finished goods packaging such as cases and master cartons

- Inbound freight for the above materials

The chart uses Q1 of 2020 as a starting point on which percent increases are based. The figures presented are averages and lag by approximately one-half of the quarter of their actual incurrence due to inventory turns of products produced using materials at older, lower costs.

We’ve also included the dates we initiated price increases for these chemistries. In some instances, we received advanced notifications from vendors that allowed us to be proactive in our price increases. In others, we opted for a more reactive and delayed approach in passing these increases to customers due to market conditions and understanding of the need of our customers not only to be competitive but profitable, instead choosing to absorb the costs ourselves.

The relationship between increases in our costs and price increases for our customers is not 1 to 1. The figures are averages that lag slightly behind their actual incurrence, minimizing the duration and amount we absorbed costs, something we continue to do where possible to keep our customers competitive.

For example, our materials costs of silicone have increased by roughly 87% over Q1 of 2020. We’ve initiated price increases three times since then for a total customer price increase of approximately 74% over Q1 2020 pricing. For acrylics, costs have increased almost 49%, while we’ve implemented two price increases totaling 43%.

The rapid-fire nature and extent of these cost increases have placed us firmly in uncharted territory. But in challenge comes opportunity.

We’re investing in new machinery and personnel and optimizing our production scheduling to maximize efficiency. Additionally, we continue to optimize our formulations while maintaining our high-quality standard and without sacrificing product performance.

These improvements are ongoing, and all will take time to bear fruit and impact or offset rising costs in meaningful ways. For more immediate cost offsets, we look to sourcing. We continue to seek alternative suppliers and negotiate agreements with our existing vendors to lessen the impact of these decreases and hopefully delay their occurrence.

We thank you for your continued support and trust in us throughout it all. We’ll continue to be transparent as things progress and we work through these challenging conditions. Despite the uncertainty of what the future may hold, we’re sure that we’ll emerge from the other end of it a better team with stronger customer partnerships than ever.