AN INTRODUCTION TO MS POLYMER SEALANTS

Despite their comparatively recent surge in popularity, MS polymer sealants have been around since the late 1970s. Japanese company Kaneka originally developed MS polymers as a durable, highly elastic structural sealant to help protect buildings from the devastating effects of Japan’s frequent earthquakes. Since then, researchers have optimized, refined, and specialized MS polymer formulations into the versatile and performance-driven solutions used today.

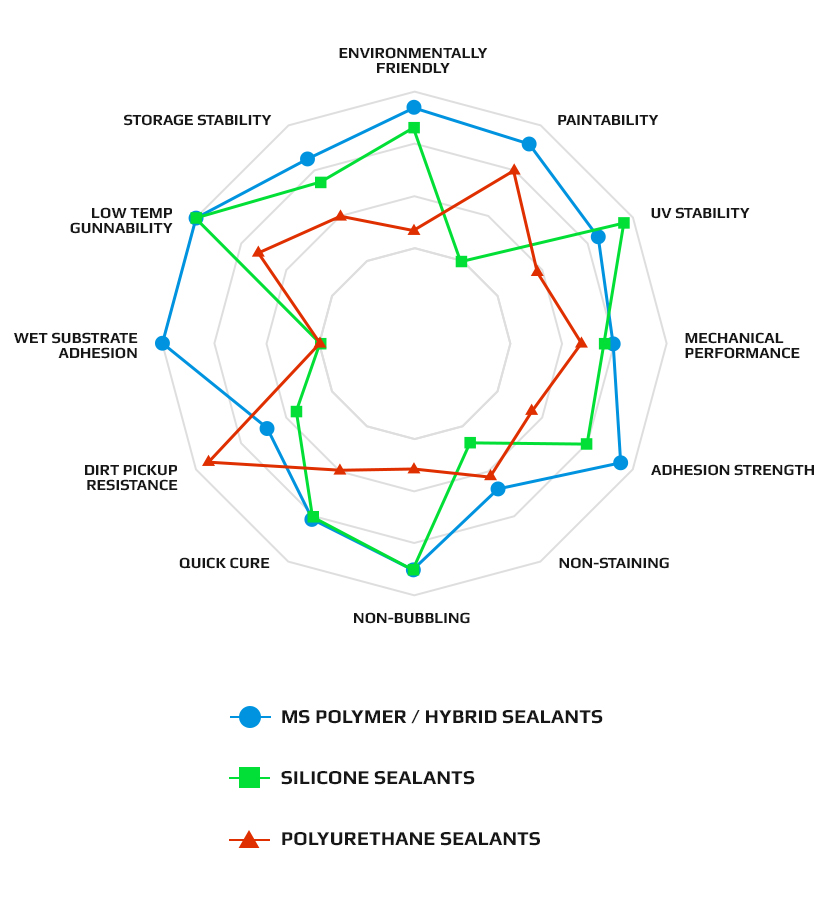

MS polymer sealants, also known as “Modified Silicone” or “Hybrid” sealants, use a modified silane polymer as their base instead of the synthetic polymer base of silicone or the urethane-based polymer system utilized by polyurethane sealants. This unique chemistry allows MS polymers, like our EvoSeal MS, to combine the high-performance characteristics of silicone and polyurethane while minimizing the weaknesses of each. For example, MS polymers possess the durability and paintability of polyurethane without the shrinkage commonly associated with polyurethane chemistries. It also has silicone’s weather and UV resistance while still standing up to abrasion.

ISOCYANATE & SOLVENT FREE

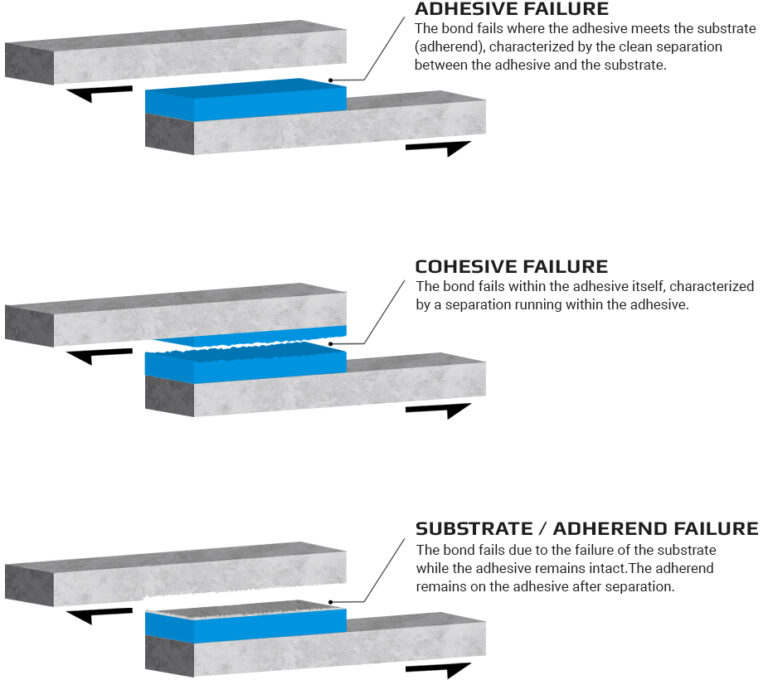

The innovative hybrid chemistry of MS polymer sealants offers many unique benefits. The silane-terminated foundation makes MS polymer sealants free of isocyanates. Isocyanates are highly reactive chemicals, which upon reaction with moisture in the air or from the substrate, releases Carbon Dioxide (CO2). These CO22 molecules form bubbles or voids within the sealant, creating an uneven appearance. Over time, these bubbles and voids can compromise the strength of the sealant, resulting in a cohesive failure.

This lack of moisture-reactive isocyanates means MS polymer sealants will adhere to wet substrates, which isn’t possible for polyurethane or silicone sealants. This wet-surface adhesion makes MS polymer sealants, like our EvoSeal MS, ideal for use in inclement conditions like rain and snow.

MS polymer sealants contain no solvents, unlike many polyurethanes. Since the main chain does not have highly cohesive segments, solvents aren’t required. The result is a low viscosity, low odor sealant that offers excellent gunnability even at low temperatures.

When sealants containing solvents cure, the solvents will evaporate, and shrinkage occurs. This shrinkage detracts from the seam’s neat and clean appearance and can reduce the seal’s performance. As the product shrinks, it can contribute to cracking and even loss of adhesion. Since MS polymer sealants contain no solvents, they will experience limited to no shrinkage.

Beyond impacting performance, isocyanates and solvents also pose serious health concerns. Isocyanates can irritate the eyes, nose, throat, gastrointestinal system, and skin. They can also cause pneumonitis, which is inflammation of lung tissue.

Many solvents used in caulks and sealants are Volatile Organic Compounds (VOCs) which can adversely affect the health of building occupants. Sealants with high VOC levels may not comply with green-building initiatives like Green Guard or LEED. MS polymer sealants’ lack of isocyanates and solvents makes them excellent for use in green building projects, hospitals, schools, or any application where limiting VOC exposure is essential.

UV STABILITY

Light, particularly ultraviolet (UV) light, is an important component of weathering and degradation. When exposed to UV light, sealants undergo chemical reactions which change the sealant’s chemical composition. This process, called photodegradation, causes discoloration, cracking, and reduced performance capabilities. The presence of isocyanates, like those found in polyurethane sealants, can add to the impact of the photodegradation process.

MS polymer sealants are formulated with light stabilizers and antioxidants to limit the impact of ultraviolet light. Since MS polymers are isocyanate-free, the effect of these light stabilizers increases, improving the sealant’s UV resistance. As a result, MS polymer sealants are UV stable. They resist discoloration, cracking, and loss of physical properties like elasticity, making them ideal for exterior applications.

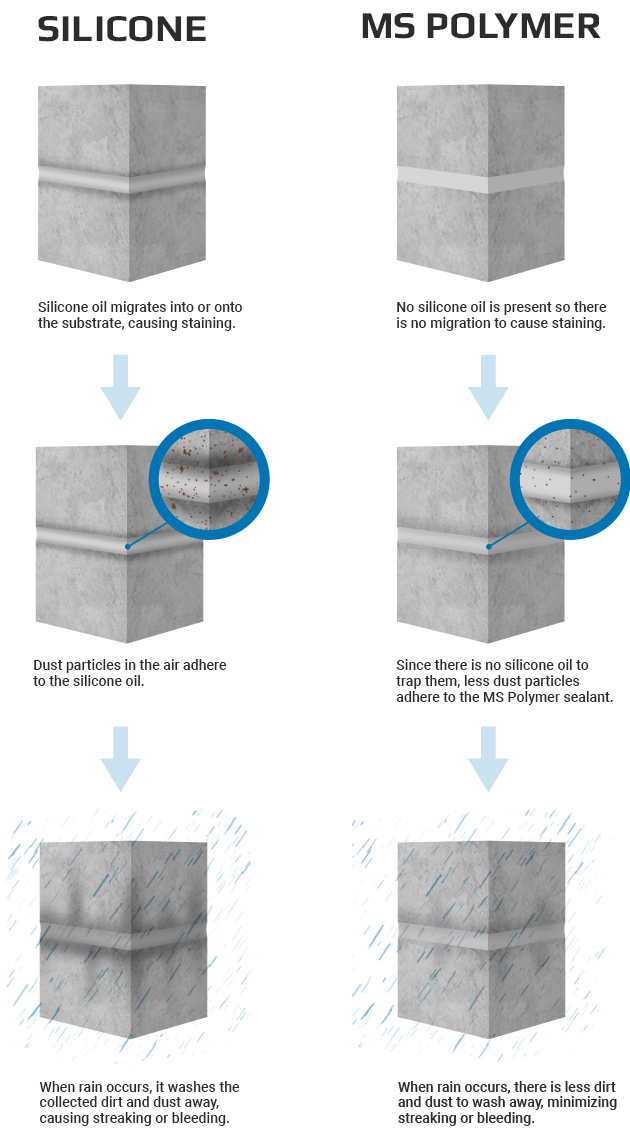

NON-STAINING / STREAKING

Many silicone sealants contain silicone oil. Over time, this silicone oil can bleed into and onto surfaces adjacent to the sealant, staining them. As this oil moves onto other surfaces, dirt and dust particles adhere to it. Once rain or other precipitation occurs, it washes these dust particles away, which leaves behind unsightly streaking.

Since MS polymer sealants do not contain silicone oil, they will not stain surfaces. Having no silicone oil also helps to limit dirt pickup, reducing unattractive streaking. It also enables MS polymer sealants to be painted with water-based paints. Painting with oil-based paints is still possible, but drying time is greatly extended.

FLEXIBLE, DURABLE ADHESION

MS polymers are also very flexible, enabling them to expand and contract with changes in temperature and humidity and absorb the vibrations from structural movement, impact, and sound. Combined with their UV stability and abrasion resistance similar to polyurethanes, MS polymer sealants offer a high degree of durability and weather resistance.

Like silicone, MS polymer sealants are chemically inert (non-reactive), which gives them a high degree of chemical resistance. This non-reactivity makes them well-suited for applications that may encounter harsh chemicals.

MS polymer sealants, like our EvoSeal MS, exhibit high-strength, permanently flexible adhesion to most substrates, including wood, metal, aluminum, glass, concrete, EPDM rubber roofing, Kynar® coated materials, many plastics, and more.

VERSATILE FORMULATION

MS polymer formulations are easily modified by blending different polymer types, adding plasticizers, fillers, or other additives. These modifications allow MS polymers to be ‘engineered’ to meet the demands of specific applications, further adding to the chemistry’s versatility.

This ease of modification, adherence to most common building materials, and their high-performance capabilities make MS polymer sealants suited to tackle a wide array of applications encountered by many different industries.

Some of these applications include:

- Flashing, coping, skylights, and gutter seams; adhering EPDM roofing membranes.

- Kitchen and bath tile, sinks, tubs, counters, and other fixtures

- Heating, ventilating, or air conditioning ductwork

- Residential and commercial windows, doors, and siding

- Exterior cladding and joints

- Foundational waterproofing and radon sealing

- Expansion joints

- Perimeter edge sealing

- Sealing of joints between multiple precast and pre-fabricated components

- Joining surfaces of different materials

- Chemical resistant seals in liquid-repellent and impermeable floors, storage tanks, basins, and silos

- RV, trailer, and specialty vehicle manufacture and repair