What is “canned” polyurethane insulating foam?

Polyurethane foam was initially developed in the 1940s for military and aviation applications. It was not until the late 1970s that new technology allowed spray foam insulation to be used widely in home construction and improvement projects.

Polyurethane spray foam chemistry primarily consists of 2 main ingredients, isocyanate and polyol resin. When mixed, sprayed, and fully cured, the foam expands roughly 30 to 60 times its liquid volume.

As the technology for equipment, manufacturing, and packaging for polyurethane foam chemistry improved, one-component canned spray foam became more portable and efficient. The ability to dispense the foam material using an aerosol-blowing agent with a straw or gun dispensing tool allowed installers to apply the foam in small “bead-type” applications.

As a result, one-component canned insulating spray foam (OCF – one-component foam) has been a game changer for professional contractors, manufacturers, industrial installers, and DIYers in pursuit of higher quality buildings and meeting the rigorous energy conservation requirements we have today.

OCF applications – Where can I apply OCF sealants

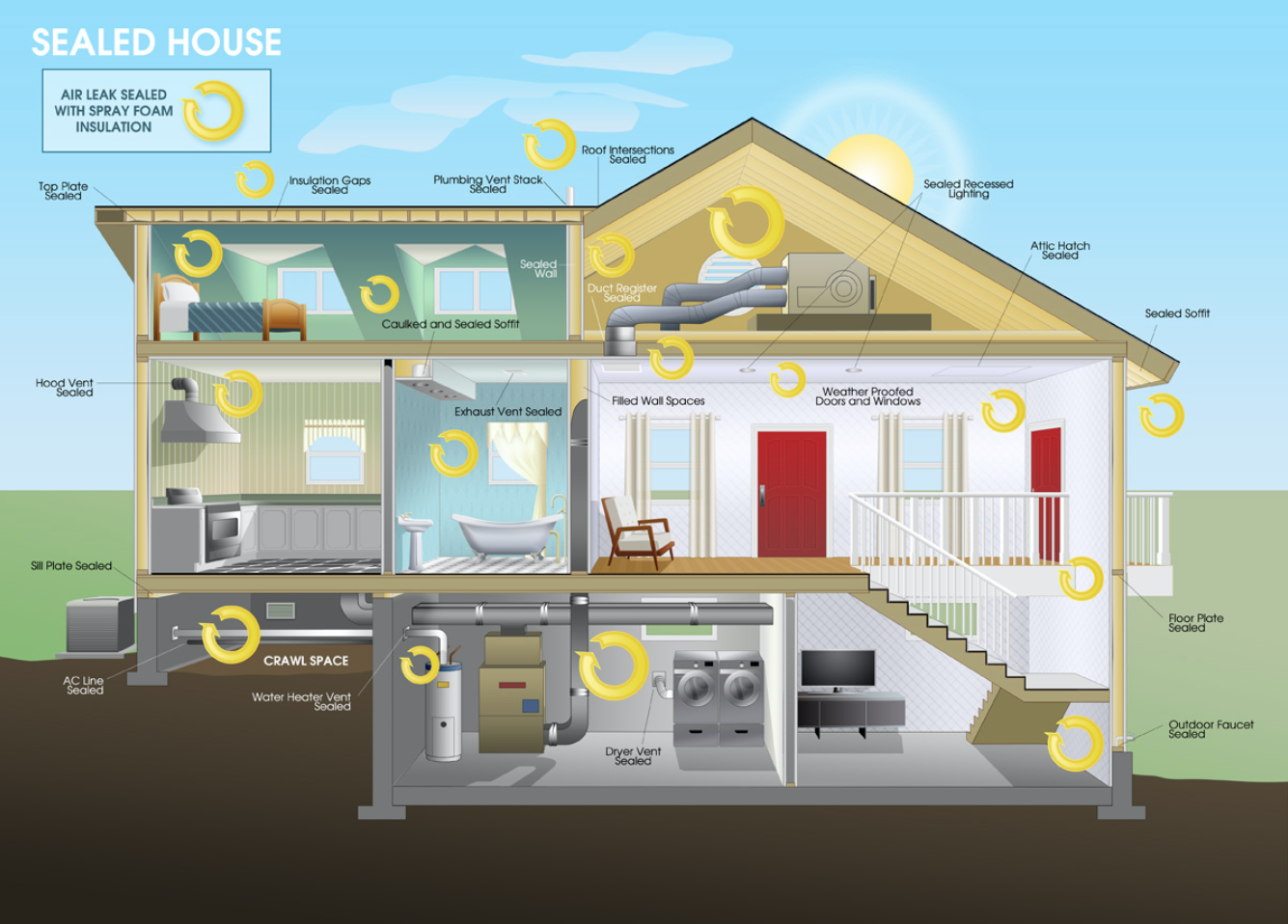

OCF sealants fill joints, seams, gaps, and cracks in wall cavities wherever air leakage can occur. Due to their expansion properties and dispensing methods, OCF sealants are highly effective for use in hard-to-reach areas and offer usage for far more applications than just insulation purposes.

INSTALLERS TYPICALLY USE EXPANDING FOAM FOR INTERIOR APPLICATIONS TO PREVENT AIR INTRUSION BY FILLING GAPS IN AND AROUND:

- basements

- crawl spaces

- attics

- floors and ceilings

- sill plates

- windows and doors.

Examples include sealing around the exterior of baseboards and vents, electrical boxes and plumbing pipes, electrical cables, or HVAC duct penetrations.

Click image to enlarge

Source Credit: Why Spray Foam, “Advantages of Spray Foam”

Due to the varying formulations available on the market and the usefulness of OCF chemistries, some spray foam sealants are also used for exterior applications and as a sealant or adhesive for landscape projects, including stone wall repair, pond/waterfall fillers, and to secure landscape blocks. Foam sealants are also widely used in the recreational vehicle and transportation industry.

Window & Door Foam Sealants

Full-Fill Pro Window & Door Insulating Foam Sealant is our single-component, low-pressure expanding polyurethane foam that ensures a watertight and airtight seal.

Designed to resist mold and enhance energy efficiency, Full-Fill Pro effectively prevents air leaks around windows, doors, wall penetrations, and sill plates.

Its low-pressure formulation adheres to a wide range of construction materials, including wood, metal, masonry, glass, and many plastics, without causing bowing or distortion of window or door frames.

SPECIFICATIONS

• UL evaluated

• AAMA 812-10 compliant

PRODUCT FEATURES

• For use in interior and exterior applications

• Will not bow or distort window/door frames

• Water, mold, and mildew resistant

• Excellent adhesion to most materials

• Improves energy efficiency

• High yield formulation

• Reduces labor and material costs

The American Architectural Manufacturers Association (AAMA) has a published standard AAMA 812-19, which addresses “The Voluntary Practice for Assessment of Frame Deflection When Using One Component Polyurethane Foams for Air-Sealing Rough Openings of Fenestration Installations.” This practice identifies pressure build and dimensional stability as the key attributes contributing to the deflection of fenestration products from using one-component polyurethane foams and provides test protocols for assessing these key attributes.

Using spray foam sealants around the perimeter of windows or doors can be a critical component to installation for sealing drafts and increased energy efficiency. However, using an unsuitable OCF sealant for this application that has not been tested to AAMA 812 could potentially warp, distort, or bow out the window frames, causing costly damage. It is essential to ensure the insulating foam product manufacturers’ labeling and installation instructions specifically reference window and door applications. This should include claims of low-pressure build or minimal expansion and offer 3rd party testing documentation for AAMA 812.

Gun Dispensed OCF

More popular amongst professional contractors and high-volume users, foam gun dispensing tools are the preferred choice for those that require speed, precision, and efficiency in installation. After shaking the can, the applicator inverts the “gun foam” OCF canister and screws it onto a foam gun dispensing tool.

This tool has a flow-control dial that allows users to adjust the bead size to match their desired output and control the dispensed foam more comfortably. The longer foam gun barrel enables the installer to apply the foam in harder-to-access spots more efficiently and effectively.

Foam guns can range from close to “disposable” in quality at a very economical price to higher priced, professional models made of high-quality components designed for precision, durability, and longevity. Foam gun dispensing tools come in a variety of options with different handles, valves, flow-control dials, and barrel lengths. Of course, you get what you pay for, and the installer should properly clean and maintain their foam guns like any other tool they depend on to perform top-quality craftsmanship.

Foam gun cleaner

Necessary when using a foam gun dispensing tool, foam gun cleaner is part of maintaining and caring for your foam gun. Cured foam tends to build up on the tip and clog the nozzle, and lack of care and cleaning could result in shorter gun life. Foam gun cleaner is basically “acetone in a can” and is sold in 12 and 16-fluid-ounce canisters that screw onto the foam gun. Once the can is attached to the gun, the user squirts the foam gun cleaner through the dispensing tool until the foam is completely removed from the barrel and nozzle. Then the foam gun is ready to be stored.

The foam cleaner typically comes with a screw-on spray nozzle that allows the user to spray the exterior of the gun or on a rag to wipe any excess foam that may have accumulated during usage. If the user needs to continue using the foam gun, it is recommended to switch foam canisters without cleaning the inside of the gun and leave the foam canister on the gun until removed for storage.

WANT TO LEARN MORE ABOUT FOAM SEALANTS?

Visit our full blog on All About Spray Foam Sealants to learn more.

What is “canned” polyurethane insulating foam?

Polyurethane foam was initially developed in the 1940s for military and aviation applications. It was not until the late 1970s that new technology allowed spray foam insulation to be used widely in home construction and improvement projects.

Polyurethane spray foam chemistry primarily consists of 2 main ingredients, isocyanate and polyol resin. When mixed, sprayed, and fully cured, the foam expands roughly 30 to 60 times its liquid volume.

As the technology for equipment, manufacturing, and packaging for polyurethane foam chemistry improved, one-component canned spray foam became more portable and efficient. The ability to dispense the foam material using an aerosol-blowing agent with a straw or gun dispensing tool allowed installers to apply the foam in small “bead-type” applications.

As a result, one-component canned insulating spray foam (OCF – one-component foam) has been a game changer for professional contractors, manufacturers, industrial installers, and DIYers in pursuit of higher quality buildings and meeting the rigorous energy conservation requirements we have today.

OCF applications – Where can I apply OCF sealants

OCF sealants fill joints, seams, gaps, and cracks in wall cavities wherever air leakage can occur. Due to their expansion properties and dispensing methods, OCF sealants are highly effective for use in hard-to-reach areas and offer usage for far more applications than just insulation purposes.

INSTALLERS TYPICALLY USE EXPANDING FOAM FOR INTERIOR APPLICATIONS TO PREVENT AIR INTRUSION BY FILLING GAPS IN AND AROUND:

- basements

- crawl spaces

- attics

- floors and ceilings

- sill plates

- windows and doors.

Examples include sealing around the exterior of baseboards and vents, electrical boxes and plumbing pipes, electrical cables, or HVAC duct penetrations.

Click image to enlarge

Source Credit: Why Spray Foam, “Advantages of Spray Foam”

Due to the varying formulations available on the market and the usefulness of OCF chemistries, some spray foam sealants are also used for exterior applications and as a sealant or adhesive for landscape projects, including stone wall repair, pond/waterfall fillers, and to secure landscape blocks. Foam sealants are also widely used in the recreational vehicle and transportation industry.

Window & Door Foam Sealants

Full-Fill Pro Window & Door Insulating Foam Sealant is our single-component, low-pressure expanding polyurethane foam that ensures a watertight and airtight seal.

Designed to resist mold and enhance energy efficiency, Full-Fill Pro effectively prevents air leaks around windows, doors, wall penetrations, and sill plates.

Its low-pressure formulation adheres to a wide range of construction materials, including wood, metal, masonry, glass, and many plastics, without causing bowing or distortion of window or door frames.

SPECIFICATIONS

• UL evaluated

• AAMA 812-10 compliant

PRODUCT FEATURES

• For use in interior and exterior applications

• Will not bow or distort window/door frames

• Water, mold, and mildew resistant

• Excellent adhesion to most materials

• Improves energy efficiency

• High yield formulation

• Reduces labor and material costs

The American Architectural Manufacturers Association (AAMA) has a published standard AAMA 812-19, which addresses “The Voluntary Practice for Assessment of Frame Deflection When Using One Component Polyurethane Foams for Air-Sealing Rough Openings of Fenestration Installations.” This practice identifies pressure build and dimensional stability as the key attributes contributing to the deflection of fenestration products from using one-component polyurethane foams and provides test protocols for assessing these key attributes.

Using spray foam sealants around the perimeter of windows or doors can be a critical component to installation for sealing drafts and increased energy efficiency. However, using an unsuitable OCF sealant for this application that has not been tested to AAMA 812 could potentially warp, distort, or bow out the window frames, causing costly damage.

It is essential to ensure the insulating foam product manufacturers’ labeling and installation instructions specifically reference window and door applications. This should include claims of low-pressure build or minimal expansion and offer 3rd party testing documentation for AAMA 812.

Gun Dispensed OCF

More popular amongst professional contractors and high-volume users, foam gun dispensing tools are the preferred choice for those that require speed, precision, and efficiency in installation. After shaking the can, the applicator inverts the “gun foam” OCF canister and screws it onto a foam gun dispensing tool.

This tool has a flow-control dial that allows users to adjust the bead size to match their desired output and control the dispensed foam more comfortably. The longer foam gun barrel enables the installer to apply the foam in harder-to-access spots more efficiently and effectively.

Foam guns can range from close to “disposable” in quality at a very economical price to higher priced, professional models made of high-quality components designed for precision, durability, and longevity. Foam gun dispensing tools come in a variety of options with different handles, valves, flow-control dials, and barrel lengths. Of course, you get what you pay for, and the installer should properly clean and maintain their foam guns like any other tool they depend on to perform top-quality craftsmanship.

Foam gun cleaner

Necessary when using a foam gun dispensing tool, foam gun cleaner is part of maintaining and caring for your foam gun. Cured foam tends to build up on the tip and clog the nozzle, and lack of care and cleaning could result in shorter gun life. Foam gun cleaner is basically “acetone in a can” and is sold in 12 and 16-fluid-ounce canisters that screw onto the foam gun. Once the can is attached to the gun, the user squirts the foam gun cleaner through the dispensing tool until the foam is completely removed from the barrel and nozzle. Then the foam gun is ready to be stored.

The foam cleaner typically comes with a screw-on spray nozzle that allows the user to spray the exterior of the gun or on a rag to wipe any excess foam that may have accumulated during usage. If the user needs to continue using the foam gun, it is recommended to switch foam canisters without cleaning the inside of the gun and leave the foam canister on the gun until removed for storage.