This article is the second of a two-part article series focusing on sound. For part one, a primer focused on the basics of sound and sound reduction, click here.

In the previous entry of our series on sound, we touched on the basics of sound and the main principles of sound reduction and isolation. One of those principles was that of Conduction; more specifically, the concept of flanking pathways. This is particularly relevant due to the role it plays in sound reduction and the usage of acoustical sealants to mitigate that role. In this entry, we’ll discuss the effects of flanking paths and flanking noise. Additionally, we’ll explain the role an acoustical sealant like our Sound Seal 90 Smoke, Draft, and Acoustical Sealant differs from standard latex or silicone caulks and how it can help reduce flanking noise. Finally, we’ll detail the proper application of the acoustical sealant to resume the sound reduction integrity of the assembly.

WHAT IS FLANKING NOISE?

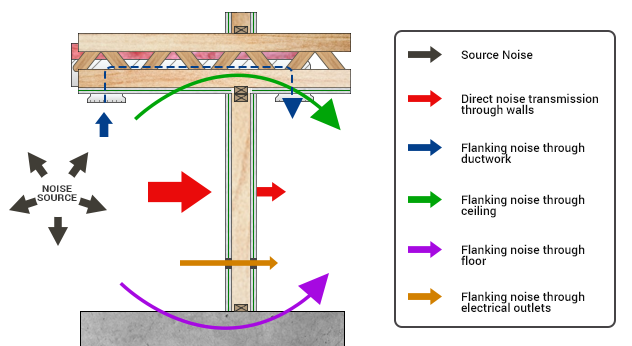

In simple terms, flanking noise is the noise which reaches a room by an indirect method; by going over, under, or around barriers intended to provide sound or noise control. Sound, much like air and water will take the path of least resistance between rooms. The routes that sound takes to bypass sound reduction efforts are called flanking paths. While this facet of sound reduction is rarely talked about, it can have huge ramifications in the success of your sound reduction efforts. You may have spent a lot of time planning and money constructing a high performing partition, making sure to address the key principles we discussed in our previous entry – only to find the level of sound reduction nowhere near your desired level.

That’s because no assembly can ever perform better than the level of surrounding flanking noise. In the scenario below, there is no way to improve the performance of the wall. The wall is not failing, the adjacent surfaces are. In order to ensure the sound partition is performing as it should and resulting in the desired level of sound reduction, the flanking paths of the surrounding structures must be addressed.

Common flanking paths include:

- Ceilings – Air and sound leakage around partition walls at ceilings.

- Doors – Air and sound leakage around doors.

- Ductwork – Shared ductwork between rooms creates a direct path for sound to travel.

- Electrical receptacles & light switches – Air and sound leakage around unsealed electrical outlets, switches, or boxes.

- Floor noise transmission – Floor coverings extending beneath partitions into adjoining rooms create flanking path.

- Framing connections – Even in decoupled frame design, a solid path through a band joist or drywall panel creates a flanking path for sound.

- Plumbing penetrations – Air and sound leaks through the penetrations as well as plumbing chaseways that pass between areas.

- Resilient channel mistakes – Improperly placed screws that penetrate into studs or joists.

- Partition edge abutments to adjoining walls, ceilings, and floors.

Each of these sources of flanking noise can be minimized in different ways. We’ll be focusing on a few key flanking paths and how the application of acoustical sealants such as our Sound Seal 90 Draft, Smoke, and Acoustical Sealant can be used to minimize their impact.

UNDERSTANDING ACOUSTICAL SEALANTS

It is important to understand that acoustical sealants aren’t the same as ordinary silicone or latex caulk. The key difference to note is that acoustical sealants are formulated to remain permanently flexible. Over time, a sealant will experience expansion and contraction due to fluctuations in humidity, as well as shearing stress caused by slight movement of the built structure. Caulks that do not remain flexible can eventually crack or shrink, or separate from the substrates – both causing the seal to fail and creating a seam or gap that allows for the passage of sound.

Additionally, a good quality acoustical sealants will show reduced shrinkage in comparison to standard caulks. Shrinkage of the sealant can result in the bead tearing away from one or more of the substrates, once again creating a pathway for sound to travel through. Our Sound Seal 90 experiences only 15.4% shrinkage, compared to the 20-25% exhibited my other acoustical sealants.

A quality acoustical joint sealant will have been tested by accredited laboratories to meet a host of standards and specifications. ASTM-C834 for example, is a standard which classifies a latex sealant according to its flexibility based on the results of many other tests. ASTM-E90 measures the sound transmission loss of building partitions and elements.

Many of these tests or certifications are required by building codes as per the ICC’s International Building Code (IBC). For example: IBC Section 120.7 states that “Walls, partitions, and floor/ceiling assemblies separating dwelling units from each other or from public or service areas shall have a sound transmission class (STC) of not less than 50 for air-borne noise when tested in accordance with ASTM-E90. Penetrations or openings in construction assemblies…shall be sealed, lined, insulated, or otherwise treated to maintain the required ratings.”

An important understanding to have and one that many often times confuse is the relationship between an acoustical joint sealant and an STC rating. STC ratings apply to the entirety of the system itself: partitions, ceilings, floors, doors, windows, and exterior wall configurations, and not necessarily to their individual components. These assemblies are usually tested in laboratory settings in order to identify their sound reduction potential, expressed as an STC value. These environments are highly controlled, with great pains to minimize the effect of flanking noise that that the results reflect the performance of the partition itself.

In the field, however, conditions are much different. Typically, the assembly will exhibit lower performance than in laboratory conditions due to the existence of flanking noise. This noise can be present at the time of initial construction & insulation, or when the assembly is altered post-installation (one may add an additional outlet, or cut out to accommodate mounted television wires, for example).

In such cases, acoustical joint sealants are used only to resume (and in some cases improve) the sound reducing integrity of the assembly. No acoustical joint sealant inherently carries an STC rating. Any stated STC rating is simply the highest STC rated assembly that sealant has been used or tested in to resume the integrity of.

USING ACOUSTICAL SEALANTS

Typically, acoustical sealants are used in the following applications to reduce flanking noise, thus enabling the wall to achieve, maintain, and potentially improve the desired level of sound reduction:

- Top and bottom runners prior to application of drywall

- Outer edge perimeter joints of drywall

- Cut-outs and utility penetrations

- Bottom of wall, wall to wall, and head of wall joints

- Penetrations for metallic, insulated metallic and non-metallic pipe, ducts, conduits, cables, and wires in non-fire rated smoke partitions and/or acoustical assemblies

- In conjunction with resilient mounts (such as resilient channels or sound clips)

When applying an acoustical sealant it is critical to ensure you achieve a high quality seal. Seal quality is essential in minimizing sound transmission through these flanking pathways. Even the slightest seal failure can have huge ramifications – a gap that makes up 1% of surface area can allow 50% of the sound to pass through it.

Ensure that all surfaces are cleaned of any debris or material that may prevent or deter adhesion. Common debris types include dirt, loose particulate, existing sealants, grease, etc.

Load a tube of acoustical sealant into a standard quart sized caulking gun. We recommend our Sound Seal 90 Draft, Smoke, and Acoustical Sealant.

Cut nozzle to allow recommended bead size. Bead size may range from 3/8″ to 1/4″, depending on application.

Apply sealant on underside of all runners at the ceiling and floor prior to the installation of drywall, the outer edge perimeter joints, cut-outs, and utility penetrations. Apply sealant to the joint where partial drywall sheets meet window and door frames.

- When sealing cutouts in drywall made to accommodate utility penetrations such as electrical outlets or light switches, coat the the inside perimeter of these cutouts. Boxes should be installed before sealant sets. Instead of a sealant, putty pads like our Fire-Rated Putty Pads, may be used.

- When filling gaps larger than 1/4″ around, fill with loose filler material or backer rod before applying acoustical sealant to complete the filling. Backer rod width should be roughly twice the width of the gap to be caulked.

Sound Seal 90 has a tooling time of approximately 15 minutes. The sealant may be tooled using finger, putty knife, spatula, or other means. Use water or wet cloth to clean tools and excess sealant following each installation. Due to the permanent flexibility of acoustical sealants, any residual amounts may interfere with adhesion and compromise the quality of the seal or adhesion to additional products like drywall tape or other joint compounds.

If using a bulk caulking gun, load sealant into gun as directed by bulk gun manufacturer or sealant manufacturer.

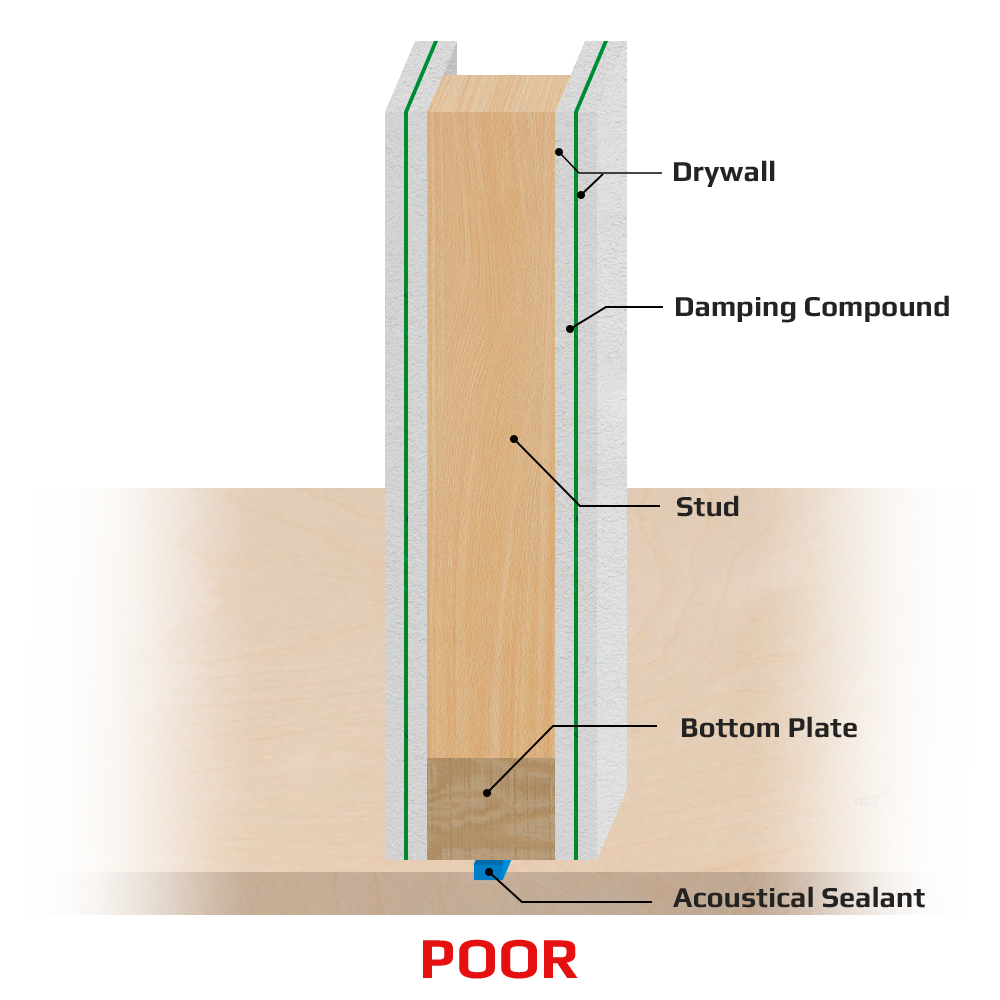

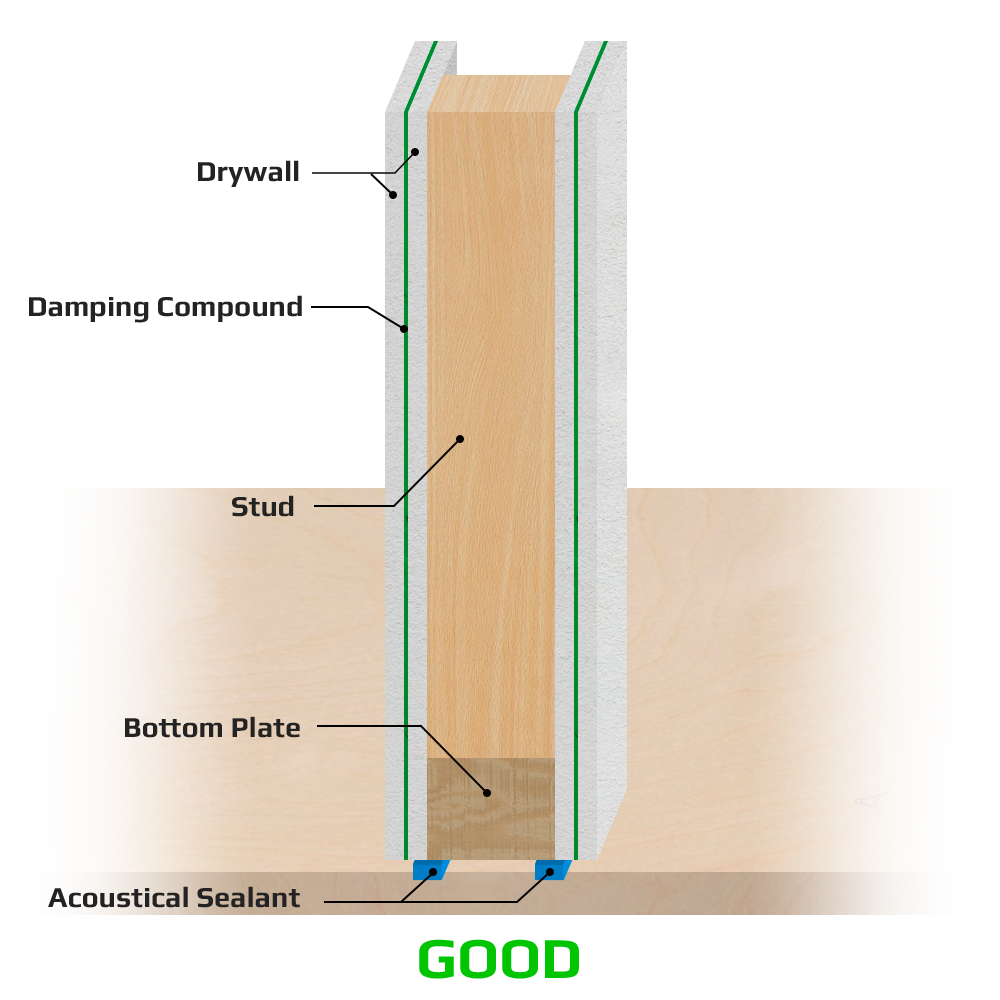

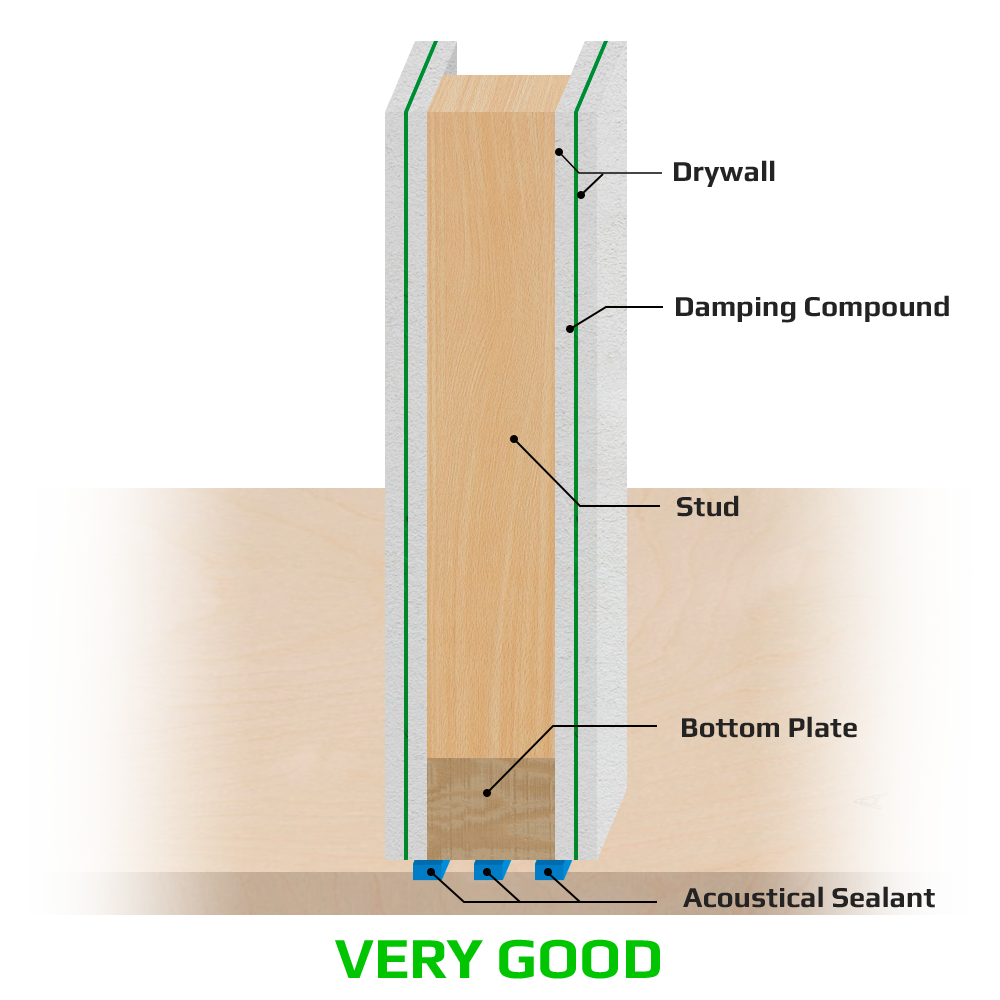

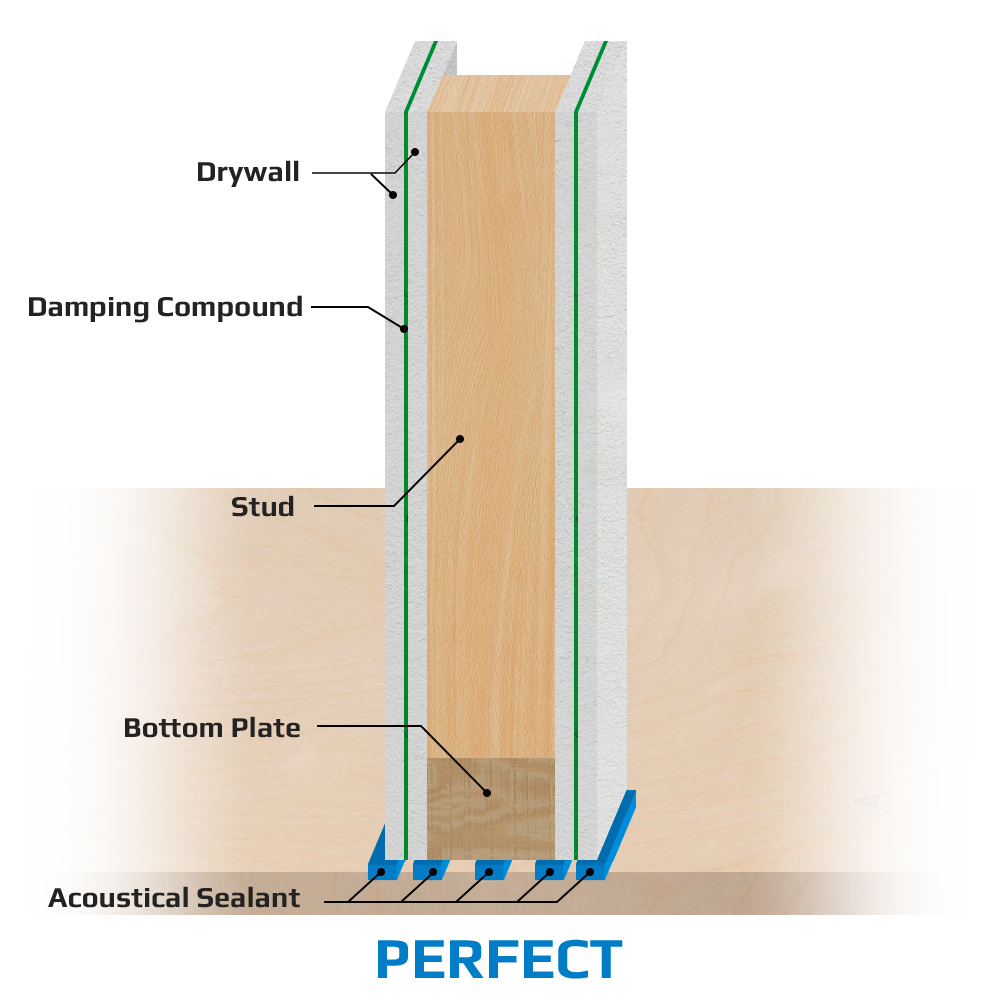

The below diagrams illustrate different levels of acoustical caulk sealing applications:

POOR QUALITY

VERY GOOD QUALITY

PERFECT QUALITY

The acoustical sealant is applied in a heavy bead under the bottom plate, as well as each drywall layer. this ensures that each gap or seam at every intersection is sealed and provides multiple layers of redundancy. In this scenario, the quality of the individual seals are backuped up by the additional layers.

Of course, this isn’t the only way to achieve near perfect seals, just an example. Many different patterns can be used successfully. Eventually, the number of seals will become irrelevant, as 6, 10, or even 100 perfect seals aren’t notably different than only 2 (one located on each side of the wall). However, the redundancy created by the additional seals helps to ensure that the assembly will retain its sound reduction capabilities even if one seal fails.

Even the highest rated and best constructed assembly will fail to achieve its sound reduction potential if compromised by flanking noise that seeps in through ceilings, doors, ductwork, framing connections, and a host of other small seams and gaps. As such, sealing off these flanking paths and the resulting flanking noise where at all possible is just as vital as the selection of your wall, ceiling, or flooring type. The ideal way to address many of these flanking paths is with the use of an acoustical sealant. Differing from standard latex or silicone caulks, our Sound Seal 90 Draft, Smoke, and Acoustical Sealant is specially formulated and designed to remain permanently flexible, exhibit minimal shrinkage, and is tested to ensure it meet important performance specifications.